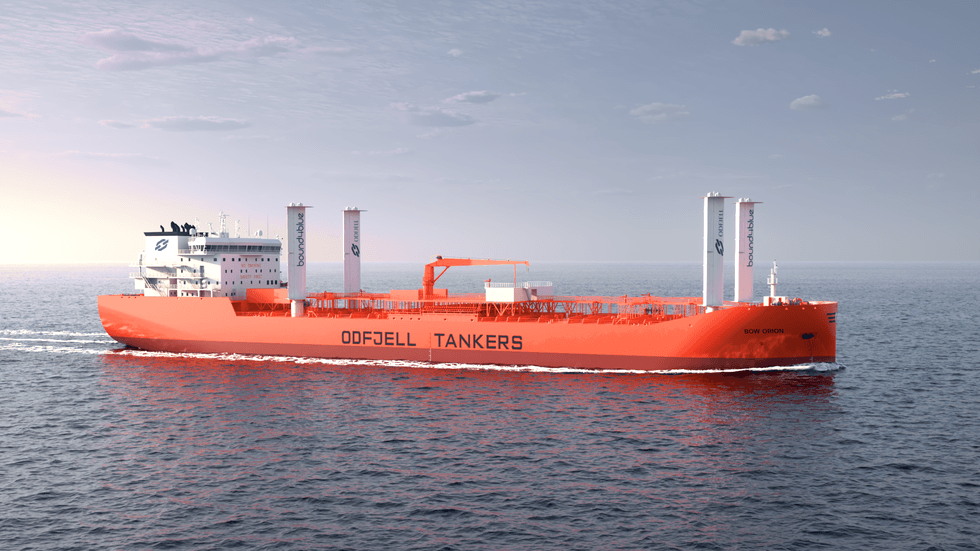

Hudong vessel with bound4blue suction sails. Illustration by NagellD

Odfjell has actively pursued decarbonization initiatives for many years, and recently documented a 51% improved carbon intensity compared to the 2008 baseline. The deployment of bound4blue's eSAIL® system represents another significant milestone in the company’s implementation of innovative solutions to increase its fleet’s energy efficiency.

"Since 2020, we have been studying sail technologies as a potential energy efficiency measure for our fleet, and we are excited to now take the next step by partnering with bound4blue to implement their pioneering eSAIL® system on one of our chemical tankers," said Jan Opedal, Manager Projects at Odfjell. “This technology has significant potential to reduce emissions by harvesting the energy on the ship itself and transforming it directly into a forward thrust.”

Redefining sailing: Merging tradition and innovation on the way to zero emissions

Odfjell's partnership with bound4blue aims to expand access to the eSAIL® technology within the tanker shipping segment and further contribute to the industry's efforts in decarbonization. The decision to collaborate with bound4blue was supported by an extensive study conducted by SSPA, evaluating various Wind Assisted Propulsion Systems (WAPS) for the Odfjell fleet. The pioneer installation will be completed in 2024.

“This project marks another leap in our dedication to decarbonization. As the first tanker company to test the suction-sail technology, we demonstrate our innovative capabilities and dedication to a more sustainable shipping sector. We all have a responsibility to use as few resources as possible, and Odfjell’s long-time efforts in energy efficiency have significantly reduced our fleet’s emissions. The work continues, and we look forward to documenting further improvements with the installation of suction sails.”

Erik Hjortland, VP Technology

“We are thrilled to team up with Odfjell for our first-ever installation in the tanker segment. They are true pioneers in innovation and sustainability, setting the bar for decarbonization in the industry. We are pleased that they have chosen our technology after their thorough analysis, confirming that we are headed in the right direction. Working with their open and collaborative team has been fantastic, and we are confident that our joint efforts will unlock significant value for the industry.”

David Ferrer, CTO, bound4blue

For more illustrations, see here.

Contacts:

Erik Hjortland, VP Technology

Tel: +47 416 96 013

E-mail: erik.hjortland@odfjell.com

Jan A. Opedal, Manager Projects

Tel: +47 951 40 875

E-mail: jan.opedal@odfjell.com

Cristina Aleixendri, COO

Tel: +34 938 337 392

E-mail: cam@bound4blue.com

About bound4blue:

bound4blue develops state-of-the-art suction sails as a turnkey solution for shipping companies seeking to reduce fuel costs and emissions. The entirely automated and easy-to-install eSAIL® system is suitable for both newbuilds and existing ships across various sectors including bulkers, tankers, Ro-Ro vessels, LNG carriers, general cargo ships, ferries, and cruise ships. The company has installed and validated the technology on three ships and has signed additional agreements with other shipowners like Louis Dreyfus Armateurs or Marubeni Corporation to install the system on their fleets. bound4blue, founded in 2014, has its headquarters in Cantabria (Spain), with additional offices in Barcelona and Singapore. Read more: www.bound4blue.com.