For any vessel, marine growth attaches to the hull and propeller while at sea. This affects the vessel's performance, decreasing efficiency and thereby increasing energy and fuel consumption.

Hull cleaning and propeller polishing conducted by underwater diving operations significantly increase performance.

The process can be performed while vessels are in the water, waiting at anchorage, at lay-by berths, and even during cargo operations. Odfjell endeavors to have all of its vessels inspected by divers twice a year, regardless of antifouling.

Analyzing performance effects

Diving inspections often reveal heavy marine fouling that needs to be removed.

In some cases, we can see a performance increase of up to 14% after a cleaning of the hull and propeller polishing.

Depending on the vessel, this can be equivalent to saving approximately 3 mts fuel per day.

The entire fleet’s performance is thoroughly analyzed on a daily basis. If lower performance is observed for a vessel, an underwater inspection may be initiated.

The effects of a hull cleaning have been well documented over the years. Fuel consumption decreases when a vessel maintains the same speed as compared to its performance prior to hull cleaning: Less fuel burned means lower CO2 emissions.

The Rupert Roughness Comparator Scale

Vendors worldwide are using the Rupert Roughness Comparator Scale to examine and determine the roughness on a propeller pre- and post-polishing.

Underwater survey operations have shown that a calcium layer will attach to the propeller over a period of five to six months. This fact has led Odfjell Tankers to conduct surveys twice a year and the propeller is polished by default.

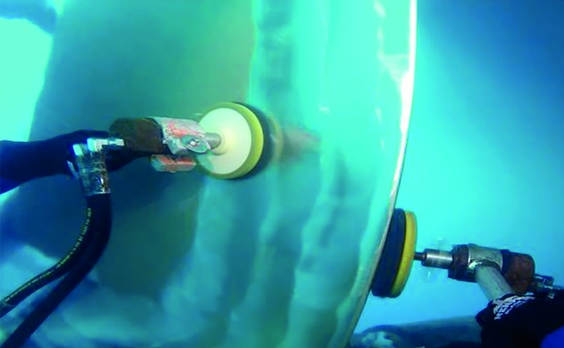

IMS Diving performing a hull cleaning

On average, surveys show that a propeller has an approximate roughness of between C and D after six months in the water. Vendors use a 3M abrasive polishing pad to remove the calcium layer before using a softer pad to achieve a grade A on the Rupert Roughness Comparator Scale.

Studies from NTNU (Norwegian University of Science and Technology) have shown that it is possible to see an approximately 0.5 knot increase if a propeller is polished from a grade E to a grade A. For a voyage from Panama to Yokohama, this can translate to a fuel saving of around 10%.

Efficiency is key for Odfjell. High-quality propeller polishing routines are important steps in improving our energy efficiency and ship performance as well as reducing our environmental footprint.